Services

Leading Provider of Oil & Gas Equipment

- Home

- Products

- Oil & Gas

- Services

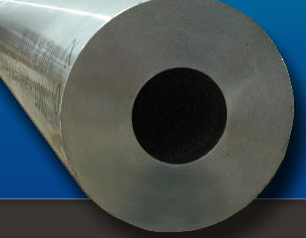

High-Strength Non-Magnetic Steel

Schoeller-Bleckmann has developed and manufactured premium steels for more than 130 years. Around 50 years ago SBO started to focus on further developing, processing and producing high-strength non-magnetic steel grades for the oilfield industry. Precociously Schoeller-Bleckmann recognised that the non-magnetic steel grades can perfectly be used for Directional Drilling.

With its group-wide, long-term experience and state-of-the-art technologies SBO has become a perfect partner to meet the highly complex requirements of an industry that has turned into a high-tech market. Schoeller Bleckmann’s non-magnetic steel excels by particularly high material strength and corrosion resistance. Special procedures such as cold-forging or finishing treatment make it highly resistant to stress corrosion. Continuous upgrading of high-grade steel alloys and machining technologies give SBO’s customers the leading edge.

Properties & Performance

Schoeller-Bleckmann non-magnetic materials are characterized by their outstanding properties and performance in the following areas:

- Non-magnetic properties

- Mechanical strength

- Endurance strength

- Pitting corrosion resistance

- Stress corrosion resistance

- Galling resistance

Material Grades

Schoeller Bleckmann offers many different grades of Non Magnetic material (P530, P530HS, P550, P580, P650 and P750) to ensure the most appropriate material can be selected for each individual application. A strategic inventory of solid and bored material is available at SB Darron Singapore’s facility to meet your immediate needs.

ANSON Circulating Hoses

ANSON steel cementing and circulating hoses incorporate the unique NOV ANSON Longlife swivel joint suitable for use up to 15,000 psi working pressure or code silver threaded swivel joints for use up to 6,000 psi working pressure. Hoses can be supplied in standard service or sour gas trim with fully traceable material certification.

ANSON Fittings

ANSON fittings encompass over 2,500 designs that include union ended tees, laterals, wye’s, goat heads, crowsfoot, union crossovers, hub crossovers, and flange crossovers. Also available are ANSON full flow and block manifold fittings: elbows (long sweep, double back, and block), tees and crosses (long sweep, full flow, and block), laterals, and goosenecks. Most fittings are manufactured from closed die forgings offering high material integrity.

Pup Joints

Mission offers the industry’s most extensive range of pup joints, including forged integral, welded, threaded, and NPST styles. All ANSON pup joints are available for standard or sour gas service (NACE MR-01-75/ISO 15156) and are supplied with full material traceability and certification.

Hammer Lug Unions (Sour Gas Unions)

ANSON hammer lug unions are available in hydrogen sulphide trim (Sour Gas, H2S) with either threaded or butt weld ends. Sour gas unions are manufactured in accordance with NACE Standard MR-01-75 (Latest Revision). All unions are subjected to rigorous inspection checks throughout manufacture. Sour gas unions have their batch numbers prefixed by letters S G and, for ease of identification, are painted olive green. Note: Most unions for sour gas service are pressure de-rated.

Hammer Lug Unions (Butt Weld Unions)

ANSON hammer lug unions are available in all Fig. numbers as butt weld unions as an alternative to the Standard API threaded end. The only exception to this being the Fig. 50 which is available as socket weld only. When ordering butt weld unions please state the pipe schedule required.

Hammer Lug Unions (Threaded Unions)

A full range of API line pipe threaded unions are available from Fig. 50 through to Fig. 1502. Threads are gauged with calibrated working API gauges which, in turn, are checked regularly with API master gauges. In addition, unions with BSP or NPT threads can be supplied upon request.

Hammer Lug Unions (Specials)

In addition to the wide range of hammer lug unions shown, Mission regularly manufactures specials to suit customers’ specific requirements in regards to materials, dimensions, and types.

Seals

ANSON lip and ‘O’ ring type seals are available for standard service in nitrile and for sour gas service in fluoroelastomer. Manufacture is closely monitored to guarantee the correct shore hardness and composition. Sour gas ‘Superseals’ are molded in special materials to resist explosive decompression for safety and reliability.

ANSON Flowheads

ANSON flowheads offer compact design resulting in reduced overall size and weight therefore increasing ease of operation. All valve seat pockets can be CRA625 inlaid to offer increased service life. The flowheads can be supplied complete with a string swivel if required. ANSON string swivels allow rotation around the string and eliminate torque transfer. They are complete with locking keys to prevent string thread back-out. Excessive testing including high temperature cyclic and slurry testing is carried out for ANSON swivels.

ANSON flowheads are available with working pressures from 2,000 psi through to 15,000 psi, temperatures from -75 ̊F (-59.4 ̊C) to 400 ̊F (204.4 ̊C) and sizes up to 9” API. All API 6A material classes are available in product specification levels (PSL 1, 2, 3 an 4).

73/8” API 10,000 psi Well Test Flowhead, (Conversion from handwheel operation to ANSON hydraulic actuator)

63/8” API 15,000 psi Well Test Flowhead, fully actuated compact 3 valve block design with dynamic string swivel and lower master valve